Insulation Materials Selection for Traditional Buildings

Retrofitting traditional buildings through the addition of insulation requires a careful, thoughtful approach to ensure good outcomes. One of the key aspects to consider is how moisture is managed in vapour, liquid, and solid form. Getting it right is challenging, while getting it wrong presents risks which can lead to building material degradation and negative impacts to occupant health and wellbeing.

This report provides detailed guidance into the technical aspects of moisture properties and movement mechanisms, enabling professionals and practitioners to make better informed decisions when specifying and installing insulation systems in traditional buildings.

Summary and Practitioner Guidance

For a brief overview of the key concepts, a summary is provided below. For more detailed discussion and technical depth, please refer to the full report linked above.

Achieving Moisture Balance

Traditional and modern building types differ in how they manage moisture, so it is important that materials and products ‘retrofitted’, meaning ‘added on which weren’t originally there’, are appropriate for the given building type. Understanding what is appropriate requires careful consideration of a range of material aspects and how they might impact the building systematically. Traditional building types generally benefit from materials which are moisture-open (both vapour-open AND moisture wicking), whereas modern building types generally use materials which are moisture-closed.

It is important to note that a building in a good state of repair is a must-have starting point. Building components that are damaged, damp, or otherwise compromised greatly increase the risk of moisture and structural problems down the road.

Achieving moisture balance in a building is determined by several factors, including the type of building materials, the construction type, the quality of the work, the use and occupancy, heating and ventilation, and the location and contextual factors of the building. Moisture can move in several ways through the air and through building materials, and materials can thus be described through several important characteristics and moisture transport mechanisms:

Principles of moisture transport

- Vapour Diffusion: the movement of water vapour molecules due to differences in vapour concentration, either in the air or within the pores of a material.

- Vapour Advection: the transport of water vapour caused by the movement of humid air due to air pressure differences.

- Capillary transport: the movement of liquid water within porous materials due to intermolecular forces between the water and the pore walls

- Pressure-driven flow: when water is subjected to external pressure it can be forced into or through a material

- Vapour sorption: the process of storing vapour in the pores of a material

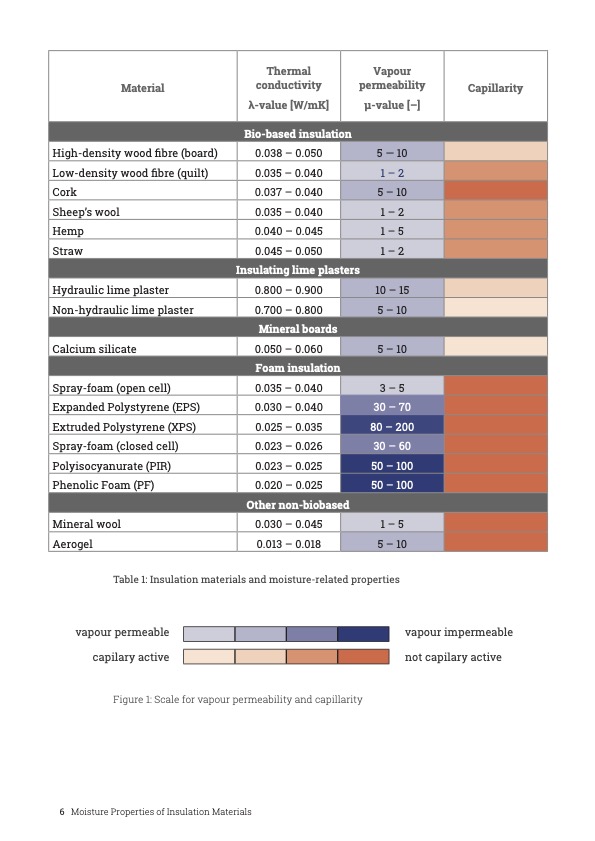

Important Hygrothermal Characteristics

- Vapour permeability: how well vapour moves through the material (μ-value)

- Hygroscopicity: the ability to buffer and release moisture from the air

- Capillary action: whether materials absorb and redistribute liquid water

- Porosity: the proportion of a material that consists of voids

- Thermal conductivity: the ability to conduct heat (λ-value)

The chart below can be used as a quick guide to various common insulating materials’ properties. A qualitative scale is used for capillary action as the precise characteristics are complex, encompassing both the rate of absorption and total moisture capacity, and which depend on the pore size distribution. The term ‘wicking’ can be used as a representation to help visualise these complex characteristics.

It is important to note that the entirety of the system needs to be considered when determining moisture balance, including wall material, insulation, vapour-control layers, renders, bonding, fixtures, paints, and coatings.

Quality Control

The execution of installation to achieve a high-quality result is of utmost importance, as poor quality can lead to a range of problems and risks as follows:

- Condensation on surfaces: air passes its ‘holding capacity’ and liquid forms, often on cold, non-porous surfaces

- Moisture accumulation within the fabric: moisture vapour within the wall or roof travels from a warmer part into a cooler part and accumulates

- Solar-Driven vapour diffusion: solar radiation heats the outer surface of the building and drives moisture back into the building

- Thermal bridges: occurring at junctions, penetrations, or areas of poor design or workmanship where insulation is interrupted, these cold spots can lead to surface condensation

- Air leaks: poor airtightness (particularly gaps in intended airtightness layers) can result in warm, humid air from the indoor environment moving to colder areas within the building fabric (e.g. behind insulation), elevating humidity or condensing as it cools

- Freeze-thaw cycles: water trapped in the pores of porous building materials, such as brick or stone, freezes and expands, generating internal pressure which can lead to material damage.

- Salt crystallisation: a physical process that occurs in porous building materials, where salts dissolved in moisture crystallise as the water evaporates. There is efflorescence, where salts form on the surface, causing white, powdery deposits that are mostly cosmetic; and subflorescence, where crystals grow inside the pores of the material, which can lead to material damage

Further Resources

Adding insulation to traditional buildings, especially in the walls, is technically challenging to get right. The building science is complicated, depends on a range of factors, and there are still aspects needing more research. That said, several resources do exist which can help the practitioner to achieve good outcomes:

- Sustainable Renovation Guide

- A Bristolian’s Guide to Solid Wall Insulation

- BS 5250:2021 – Management of moisture in buildings. Code of practice

For further resources and information regarding retrofitting traditional and heritage buildings to address climate change, increase occupant wellbeing, and reduce risk:

- PAS 2035/2030:2019+A1:2022 – Retrofitting dwellings for improved energy efficiency. Specification and guidance

- STBA Responsible Retrofit Guidance Wheel

- IHBC Climate Change Hub & Knowledge Base